If someone spends the time and effort to grow his own weed, then it’s only logical that he’d like to make his own dabs, too. Cannabis extraction requires solvents and more complicated equipment than does growing, however, and most of us aren’t scientifically savvy or rich enough to run our own systems of butane extraction — not to mention that butane cannabis extraction is very risky, and even banned in Colorado.

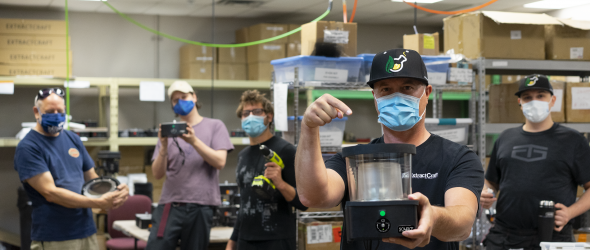

Lo and behold, there’s a machine for that. Using ethanol instead of butane for botanical extraction, ExtractCraft applies heat and pressure to strip cannabis (hemp included) of THC, CBD and the many other cannabinoids found in the plant, as well as terpenes and plant fats, depending on the form of concentrate you’re trying to make. ExtractCraft CEO Troy Ivan says that users can make anything from Rick Simpson Oil (RSO) and full-extract cannabis oil (FECO) for medical patients to potent live resin for dabbing connoisseurs. We recently talked with Ivan about how to do just that.

Westword: So is this like a closed-loop extraction system, but more simplified? How does it work?

Troy Ivan: It’s closed-loop, in the sense that what you put in there stays under vacuum within the closed system. But when you use the word “closed-loop,” you have to be careful, because people expect closed-loop systems to use butane extraction, which includes putting the plant material in the machine, with the extraction and solvent recovery both taking place in there, as well. With this equipment, it’s like a big rotating ball that sits in heated water, rotating and spinning slowly while the solvent evaporates out and collects in a jar. That’s also closed-loop, but it’s more a tabletop, personal-sized unit with a Rotovap technique.

Can you make different types of concentrate — shatter, budder, RSO — with it, or just one kind?

Yes. The machine doesn’t dictate that; [it’s] just a tool for the process. The difference between attaining a clean wax or FECO is primarily in what you do before the cannabis is put in the machine. Ethanol is very aggressive at room temperature, so it will grab everything from the plant — cannabinoids, terpenes, chlorophyll and plant fats and wax — and that’s what makes FECO so dark and swampy, because that’s what you’re going for. Now if you want to isolate the [recreational] desirables in the trichomes, you target those by freezing the plant matter and ethanol, combining them, and then only the desirable components will be grabbed.

What level of experience is required to run one of these puppies?

None. It’s super-easy. Our oldest user was a 97-year-old grandmother who makes her own meds. Our users usually range from their upper twenties to lower thirties, but a bulk of them are 35 all the way up to 75. Our website has YouTube instructional videos for new users, and then there are two user resource groups, one for non-cannabis apothecary and aroma, and then there’s another for cannabis and hemp extraction. We also have a log that offers step-by-step guides for making extractions that go in vape cartridges, how to make good stuff with trim, how to do cold-temperature extractions, and how to make RSO or FECO.

It’s all pretty easy, but it is unfamiliar. Once people become familiar with the process, though, it’s no harder than cooking.

Let’s say I have an ounce of weed testing at 20 percent THC. What do you expect the output to be? What’s the yield?

The goalpost for that is anywhere from 5 to 30 percent, depending on the quality of material and what you’re trying to make. If you’re working with quality material and know what you’re doing, you’re probably targeting somewhere between 16 and 20 percent consistently for a normal, clean wax. Working at lower temperatures won’t be grabbing off as much from the plant, though, because they’re not stripping off all those other plant materials for a cleaner yield. The cleaner waxes are more inefficient in that regard, but that also means you can run it a second time and use that second yield for infusing edibles.

How are the solvents removed after the cannabinoids are extracted?

All of the solvent will never be out; there will always be some type of molecular footprint. If you take it out of the machine, it will probably be around 3 percent alcohol, which is an absolute extract. But if you let it sit on a silicone mat to air-purge for a day or two, maybe next to a fan or something else, it will go down to just a couple of thousand parts-per-million.To go further than that and still work with stability, you would put it in a vacuum chamber to make shatter or crumble during post-processing methods.

The Source, the smaller one, has no post-processing capabilities. The larger one, the Etoh Pro, has a purge mode, which has a heated chamber that you can hook an auxiliary pump up to, to make a vacuum for post-processing.

This is always something that is focused on, and sometimes that’s because it’s not fully understood. The machine uses food-grade ethanol, and there’s not a single known adverse health effect from oral ingestion or inhalation of ethanol, unless it’s in excessive consumption. If [the extract] is liquidy, there’s probably alcohol in it, but once it becomes more stable, like wax or shatter, there will be a very, very low level in there. It’s not going to hurt you, there’s nothing poisonous about it, and it’s in such low concentration that it’s essentially negligible.

What other plants are users extracting from besides cannabis?

Oh, some crazy stuff. The blog and user groups have some cool posts about espresso, citrus-peel and egg oil extractions. People are extracting everything from tree barks to cosmetics. There’s a company that extracts berries for facial syrups, and the citrus-peel extract is treating peoples’ arthritis pains. It’s just an extraction of the terpenes from orange and lemon peels. I like to mix together espresso, vanilla and cannabis extractions and some sugar for a medicated cotton-candy drink.